I was at my local gunshop in the company of a good friend when I took note of one of the longest rifles in used rack, a very nice looking Mauser Gewehr 98 in Imperial German military trim and suspiciously good condition. It had the usual Lange Visier rear sight, bayonet lug and infantry stock, but the receiver had been reblued and every detail looked rather too pristine for a rifle that had to been made about a century ago. I had intended to ask about it, but we’d had a long wait and by the time my friend had concluded his business we were both eager to go have lunch.

A couple days later I remembered the rifle and called the gunshop to ask about the price. The clerk paused briefly, then said, “This is Dave, right? How badly do you want it?” This is the usual cue to sit down and prepare for sticker shock, but this time the news was pleasant: he could sell it to me for a mere $300. Evidently it had been in the shop for more than a year bearing a $450 pricetag and hadn’t moved because it had been rebarreled to fire an unusual ‘Schützen’ cartridge. The owner was motivated to sell, so I went over the next day and bought it.

A returning GI had brought this rifle back from Europe after WWII, and as with so many war trophy rifles, the stock had been cut just ahead of the barrel band. In collector parlance this is referred to as a ‘duffel-cut’, the idea being that with the stock shortened and the barreled action removed the rifle would be short enough to conceal inside a soldier’s duffel bag. I’ve also heard that this practice was the result of a shipping length restriction on packages being sent home. In either case, when you find a service rifle or long sporting gun with this kind of stock cut and no import markings, it is likely a vet bring-back.

The rifle had been thoroughly refurbished in Germany sometime between the world wars. Along with refinishing both wood and metal, the extractor would have been altered and magazine fitted with a wooden bock to function as a single-shot. It had been rebarreled and chambered for the 8.15x46R cartridge. The bore was is pristine condition, and the rifle came with 25 brass cases made by RWS in Germany, plus 75 cast lead bullets sized to .319″. The gunshop also threw in a set of RCBS reloading dies for an extra $20. I discovered later that this cartridge was once referred to as the 8.15 Frohn after the Suhl gunsmith credited with ‘normalizing’ its dimensions. It was a very popular cartridge in Germany before the Great War for Schützen target rifles, which were fired exclusively from the standing position at targets positioned at distances of 100, 175 or (rarely) 300 meters. Light stalking rifles chambered for this cartridge were also not uncommon. The 8.15x46R is both dimensionally and conceptually similar to the American 32-40 cartridge, and cases can be made by running 32-40 brass into a 8.15x46R sizing die then trimming to 1.82″. The rim of the 32-40 is also slightly thicker and larger in diameter than the 8.15x46R and will usually require alteration.

This Mauser 98 rifle had been adapted for ‘Wehrsport’ competition, a target discipline that combined service-type rifles with Schützen distances. The 8.15x46R was chosen over the standard German 7.92×57 service cartridge due to its popularity and because military ammunition was considered too powerful for safe use on civilian shooting ranges. This cartridge used cast lead bullets sized somewhere between .317-321″. Depending on the range facilities, many shooters could compete following the Schützen practice of using a single brass case and reloading for each shot using pre-measured powder charges wrapped in paper. The ‘Wehrmannsgewehr’ (literally “army man’s gun”) was required to have standard military features such as the bayonet mount, cleaning rod, trigger and sights, although Wehrmann rifles often featured improved rear V-notch sights with provision for windage adjustment. In the usual course of fire, the use of an aperture sight or a sling support was prohibited. Competitors were however allowed to employ shooting glasses (schießbrille) with an adjustable aperture.

The combination of a custom target-grade barrel with a Mauser action made Wehrmann rifles expensive and valued possessions. In addition to rifles re-purposed from standard Mauser 98 military actions, several companies also made purpose-build Wehrmann rifles with solid bottomed receivers. These latter are particularly sought after by collectors today and command high prices.

The 1919 Versailles Treaty banned German civilians from possessing arms chambered for military cartridges. Service rifles could be spared destruction by the Wehrmannsgewehr conversion, and my rifle appears to be an example of this. Former military markings were polished off during the process to emphasize their new civilian role. The bolt and receiver are blued rather than left bright as was standard for the German military Gewehr 98. My rifle shows only basic proof marks, a single serial number, and a manufacturer’s name on the barrel’s underside. The rear sight has been overstamped in two places to indicate elevation settings for 100 and 175 meters. I believe the rifle’s Wehrmann bolt had been lost and replaced with a standard K98k bolt. The handle was turned down rather than straight, the bolt face was the standard controlled feed rather than the fully recessed type used on other Wehrmann rifles and it lacked the expected serial number matching the receiver’s. The extractor was modified correctly but I suspect it may also have started life as a military Mauser 98 extractor. It was fitted properly to the bolt face and did not grasp cartridge rims very tightly.

The first task before shooting my newly acquired Wehrmannsgewehr was to properly repair the duffel-cut. An earlier repair attempted to reattach the forend using a wooden dowel and a steel nail or wire embedded in what appeared to be ferrule cement. The bond was so weak that I was able to wiggle this old repair apart without resorting to tools. I cleaned and squared the surfaces to be rejoined and progressively enlarged the existing hole for the cleaning rod using drills until it would accept a .25″ threaded steel rod about 6″ long. I embedded this rod on both sides of the join using a generous amount of AcraGlas gel and taped the stock and barrel together to ensure proper alignment during curing. Once the epoxy had cured the repaired stock felt as strong as ever and barrel band completely hid the repair.

An article I read mentioned that some 8.15x46R rifles had been rechambered in America for the 32-40. Since there were no markings on my rifle to indicate chambering, I made a Cerrosafe casting to confirm that it was indeed chambered for the 8.15x46R.

Loading data was fairly straightforward, as I could safely use the same starting loads recommended for the 32-40. I assembled 12 cartridges using 13.0 grains of IMR 4227 and the 178 grain cast bullets that were included with the rifle. I fired these at my local indoor range at 15 yards, where they produced very tight, consistent groups. All of the holes in the paper indicated that the bullets were properly stabilized, and the cases showed no obvious indications of excessive pressure. Two problems were noted during this initial shooting session, however. The rim of the cartridge would catch on gap between the front of the wooden magazine block and the chamber. To remove the spent case after firing, it was necessary to tilt the rifle upward and either turn it on its side or pluck the hot case out with my fingers. Also, my aging eyesight had a difficult time resolving its open sights. The rear notch was so narrow that I had great difficulty aligning while holding the front sight in focus.

I decided to replace the original follower with one that would completely fill the magazine opening and feed ramp. While I could try fashioning this from a block of hardwood or aluminum, I thought I could save some work by making a wax casting of the cavity and then taking it to a foundry and have it converted into brass. This choice was influenced by the fact that I’m acquainted with the owner of a local brass and bronze foundry. I removed the barreled action from the stock and sealed the magazine opening on the flat bottom of the receiver with gaffer tape backed with Masonite. I then melted an old candle and carefully filled the magazine cavity to the bottom of the bolt race. In retrospect, I would have done a much neater job had I used proper casting wax and pre-warmed the receiver, but the resulting wax model proved good enough. Once I got it back from the foundry it took about an hour to shape and polish the rough brass casting to fit and function the way I intended – a big improvement! It is easily removable, and therefore doesn’t permanently alter the gun.

I also fabricated another extractor with a slightly wider contact area and a closer fit between the cartridge rim and the boltface. The extractor on the Wehrmanngewehr has a shape similar to that found on the Enfield Pattern 14 rifle. To fashion my replacement extractor I used a Dremel tool to remove material from the corners of a standard military Mauser 98 extractor I had amongst my spares. The combination of a more tightly fitted extractor and lengthened brass follower made the extraction and ejection process much smoother.

I have a pair of prescription glasses that provides some help resolving open handgun sights, but they are no substitute for a proper schießbrille kit. This is an eyeglass system consisting of metal frame and a set of adjustable lens holders and accessories; the idea is to position a corrective lens so that it is precisely centered between the sight-line and the iris of the shooter’s eye, providing the maximum clarity and correction. The eyeglass holder can also be fitted with an adjustable iris that optimizes depth of focus. An opaque panel positioned in front of the non-shooting eye helps prevent it from closing, which would cause the shooting eye to dilate and reduce acuity. I had long considered acquiring a set of schießbrille, but balked at their high price ($200+) until the Wehrmanngewehr gave me the excuse I needed to order one from Germany.

I made 50 additional 8.15x46R cases using reformed and annealed 30-30 brass, a process requiring about 10-15 minutes’ work per case. I went through my initial quantity of 75 bullets in three range trips, then considered my resupply options. Cast and lubed bullets sized for the 32-40 were available from several custom bullet makers via the Internet, so I could try several weights and see what worked best in my rifle. I also wanted the option of casting my own bullets, which would require a suitable resizing die. I prefer the resize system available from Lee, but because their catalog does not include the diameter I wanted I placed a custom order from the factory. I decided on a compromise diameter of .320″ for the resize die.

Doing effective accuracy testing at my indoor range required the construction of a portable shooting bench that I could set up on one of the lanes at the far end of the line, which lacked permanent support shelves. I made my bench from plywood, using ½” iron plumbing pipe for the three legs. These could be quickly unscrewed and stuffed into a cloth sleeve I made from an old pant leg for transport. I used a kitty litter bucket as a combined carryall and shooting stool, with a padded wooden platform to sit on. My adjustable front rest and both support bags can be carried inside the bucket with room to spare.

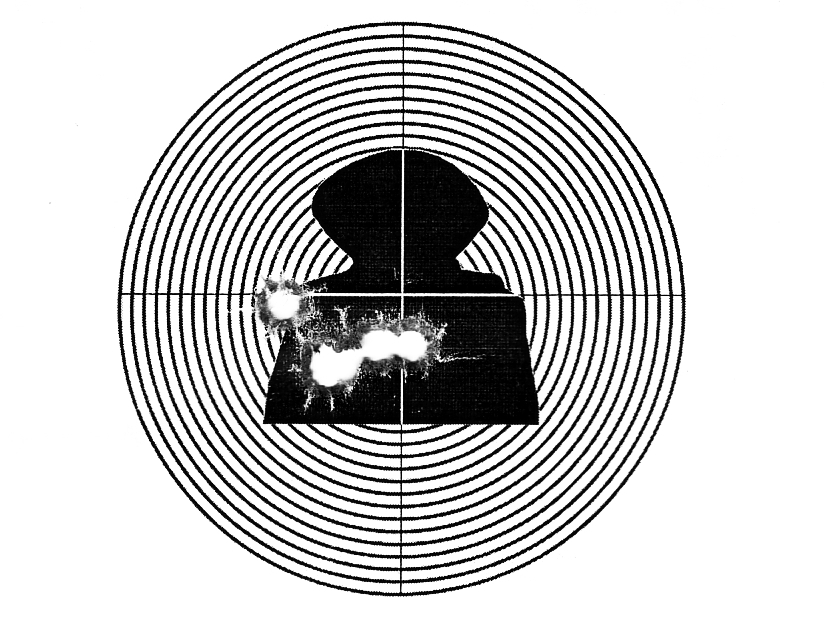

The original Wehrsport targets featured a vaguely human upper body silhouette centered in a series of concentric rings. The full sized 100-meter targets would be child’s play at 15 yards, so I made up a set of reduced sized targets for short-range practice. The tiny rings on these targets were useless for scoring purposes, but they provided a sight picture properly scaled to mimic the original targets.

This rifle has (or lacks) some customary features. The underside of the triggerguard shows that it originally had the usual pair of military stop screws, which were concealed by welding over, polishing and refinishing. The stock is relatively featureless, having neither an identification disc nor a firing pin disassembly bushing, so it may have been newly made for Wehrmann use. The only maker’s name anywhere on the rifle is stamped on the underside of the barrel: Bohler, a well-known German manufacturer of heavy ordnance. Were they responsible for the entire conversion, or did they just manufacture the new barrel? Except for proof marks and a 3-digit serial number, the receiver had been completely scrubbed of markings.

Small time collector and shooter from the wilds of Central California

Outstanding write-up, I never heard of that discipline or its prefered cartridge before. It must be really fun to bring an old gun like that back to life, thanks for sharing your methods on that.

Thanks BB!

If you’d like to learn and see more material on this subject, my main data source (in German) was the Wehrmanngewer link at this excellent site: http://www.feuerbixler.de/