Part 3 of 3: This section will focus first on specific design differences and how to differentiate each model easily. Later we will also show breakdown and pics of the parts, lots of period specific pictures of them, myths and misnomers that have been spread throughout the years, and more. It will be very pic heavy and as detailed as i can make it, and include facts that i have found recently through actual hands on experiences that directly contradict current understanding. One of these is barrel construction methods.

See part 2 HERE

Model Types

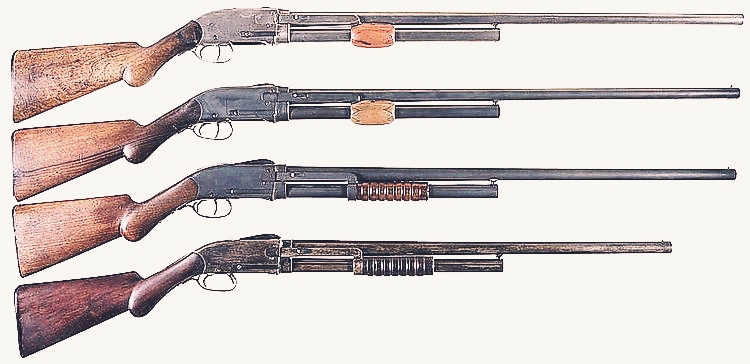

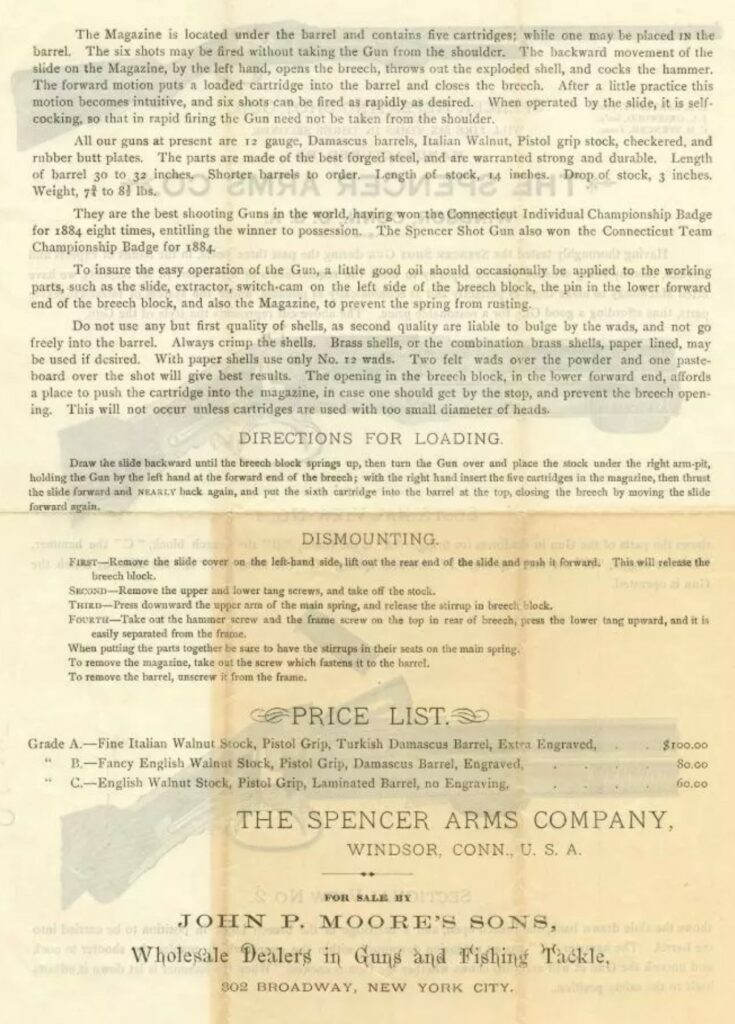

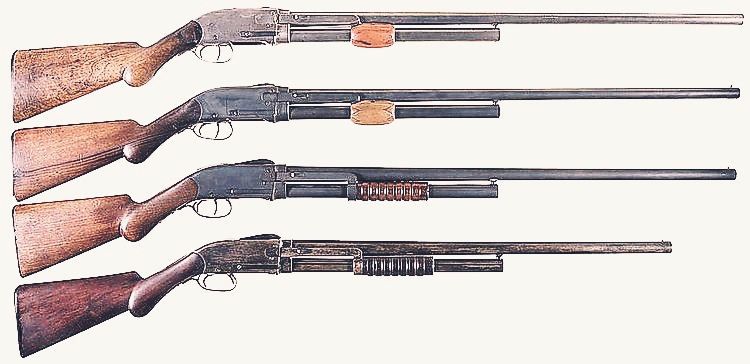

1882 Spencer

This is the first model of the Spencer shotgun. Approximately 800 were made between 1884 and 1885 in Windsor. Their first catalog printed in 1885 listed 3 grades of shotguns and these were available with 30 or 32 inch barrels, with shorter barrels available “by custom order”. They were 7 3/4 to 8 1/2lbs depending on barrel length and grades: These are easiest to identify by long control plates and the single screw on those along with them all having the trombone grip. Serials on these go to around #800.

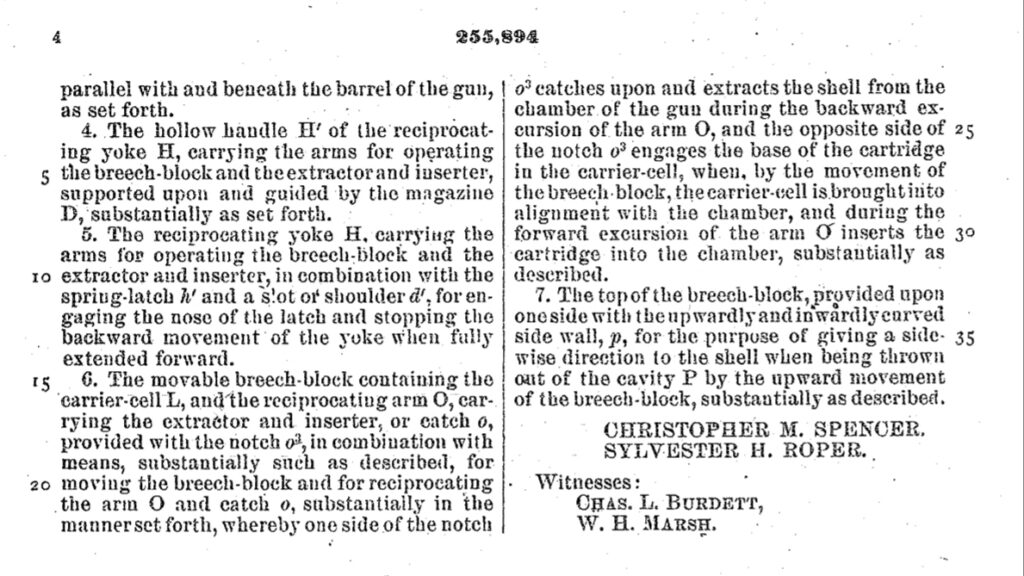

-Grade A, Finest Italian Walnut, pistol grip, Turkish Damascus barrel, Extra engraved…. $100

-Grade B, Fancy English Walnut stock, pistol grip, damascus steel barrel…. $80

-Grade C, English Walnut stock, pistol grip, Laminated(most likely fluid steel with etched pattern) barrel, no engraving…. $60

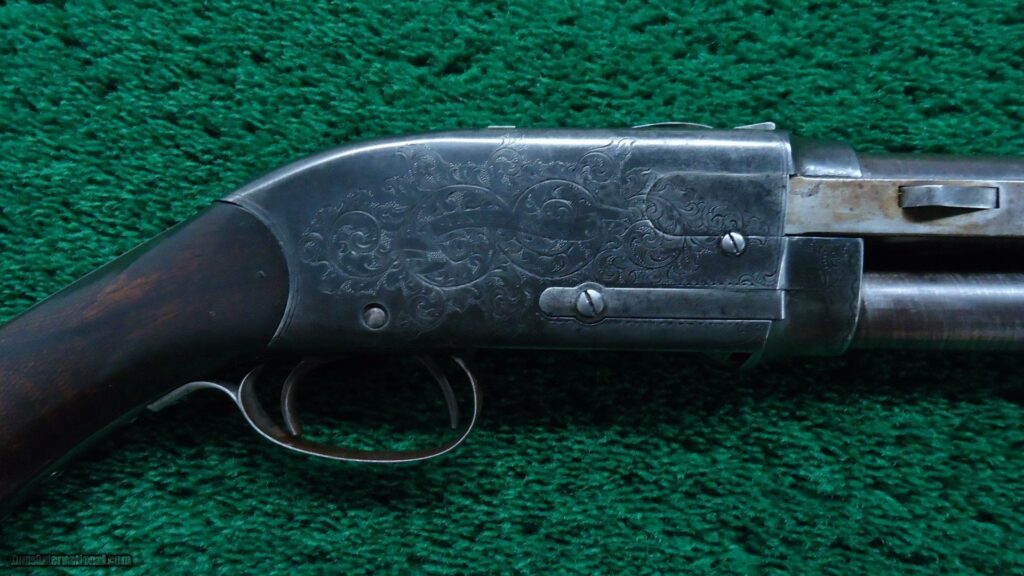

1886 Spencer

In 1886 the second model was released with the only difference being the “SPENCER ARMS.CO.WINDSOR.CT.U.S.A.PAT.APR.1882” markings added to the top of the barrel, some guard models having a longer forend, and a second screw added to the top of the control plates later on in production, some of these will retain single side plate screws though. These had the same 3 grades of gun available and barrel lengths as well. They were 7 3/4 to 8 1/2lbs depending on barrel length and grades, and there were about 1,300 of these 12 gauge models made in their only year of production. Serial numbers range from around 800-2100. Four grades of these models were available, with the newly introduced “Grade D” model being the most affordable. These are easiest to identify by a long control plate but dual screws. Serials on these go to around #2100

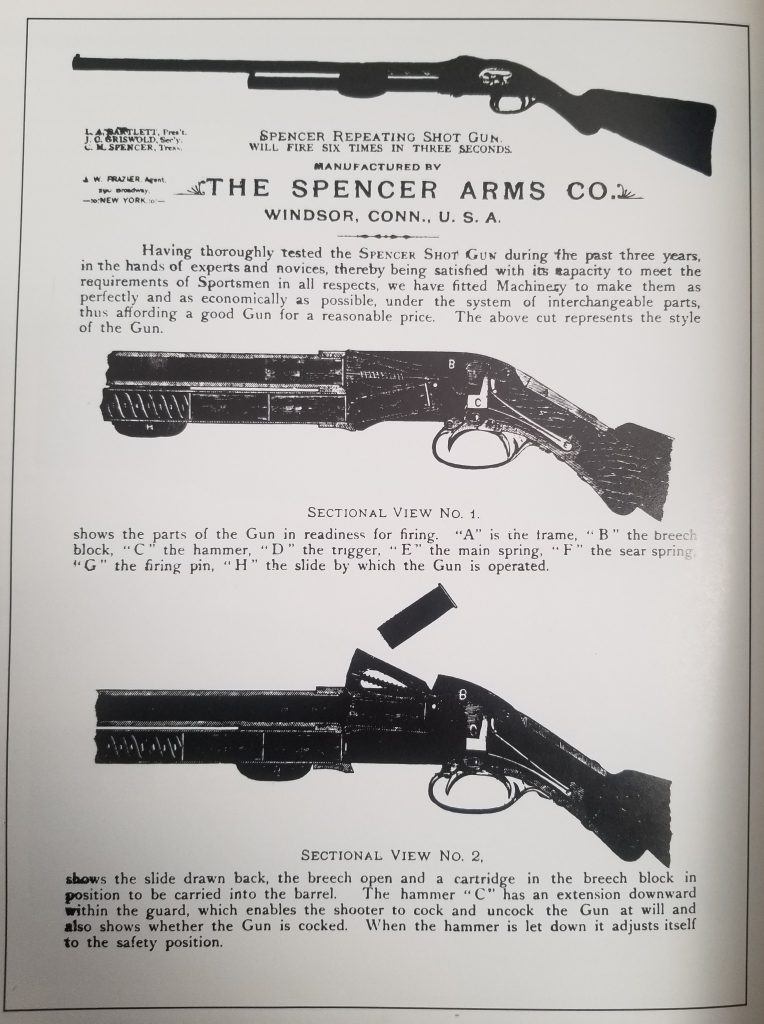

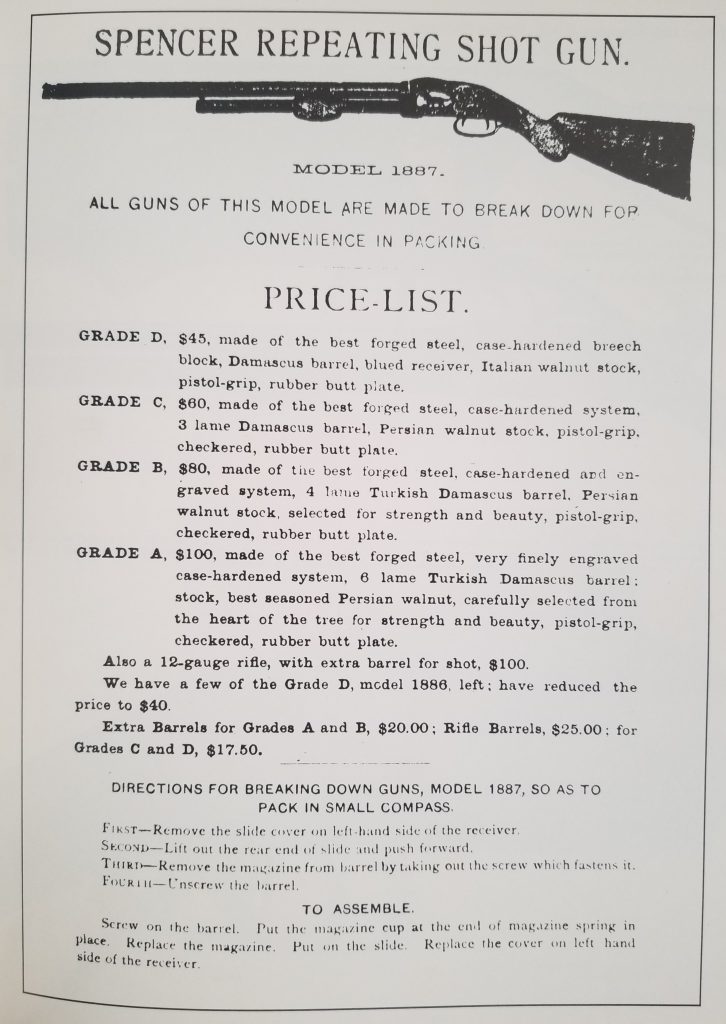

1887 Spencer

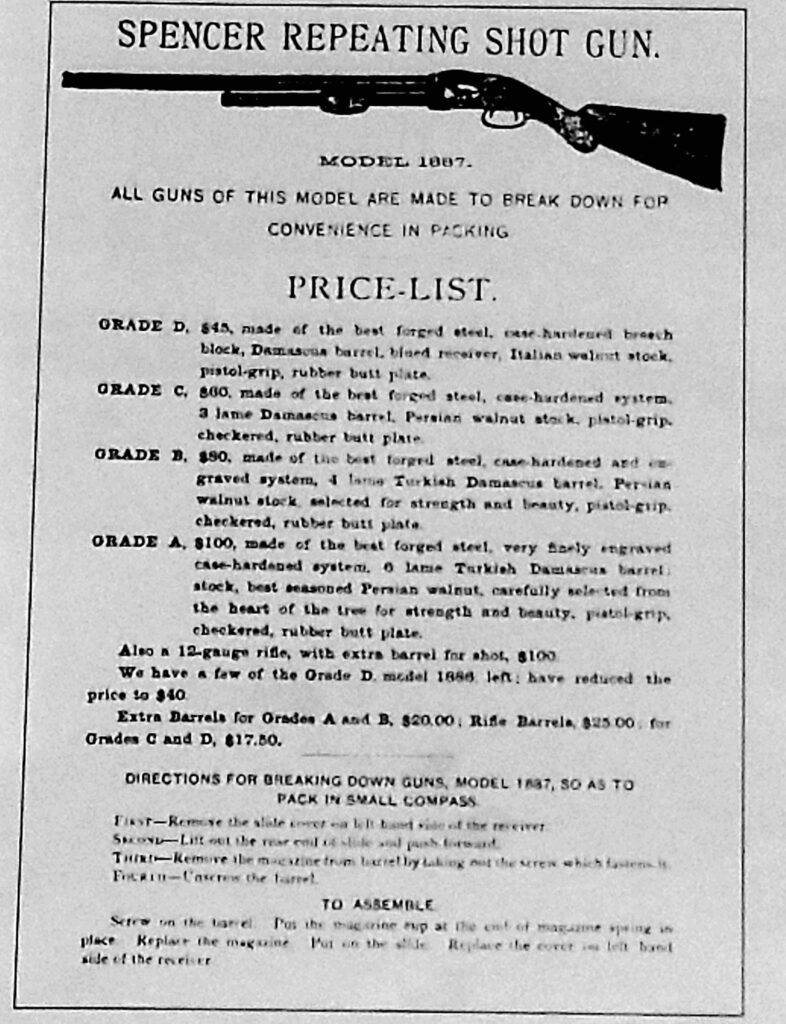

The third and final model produced by the Windsor plant was the Model 1887, made from 1887 till bankruptcy in 1889. Around 1100 of these were made in the final 3 years of production and it was not enough to sustain the company. This led to financial pressure by late 1899 and soon became bankruptcy, as payments to creditors and machinery companies like Pratt and Whitney(who owned the tooling)stopped and could no longed be payed. Four grades of these models were available, with the newly introduced “Grade D” model being the most affordable. A 12 gauge rifle was listed as being available as well on some of the ads. The only other differences present here were a new thumbscrew in the magazine tube for easier takedown, smaller right side control plate, and a lower priced “D” Grade model at $45. The one pictured below was a VERY late one with the Bannerman style rubber forend rather than a 1886 grooved wooden “guard gun” style one. These are easiest to identify by the short control plates with 2 screws and lack of Bannerman markings. Serials on these go to around #3236

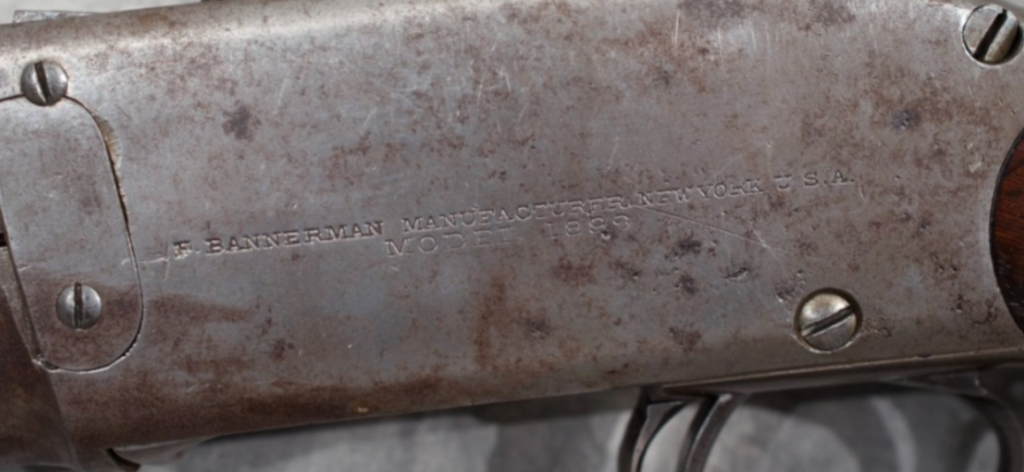

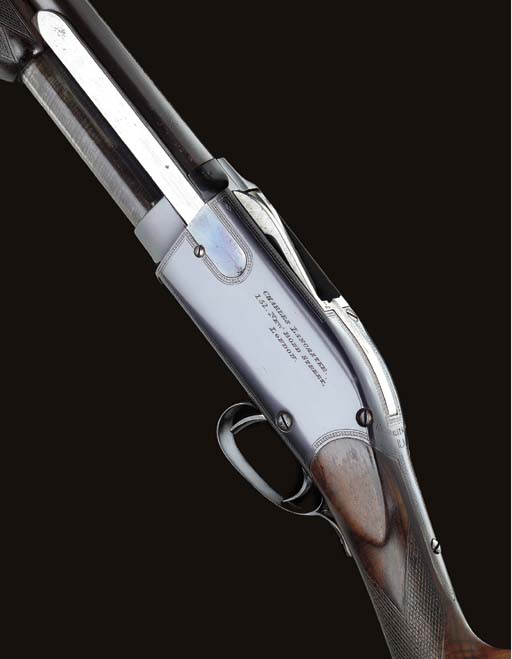

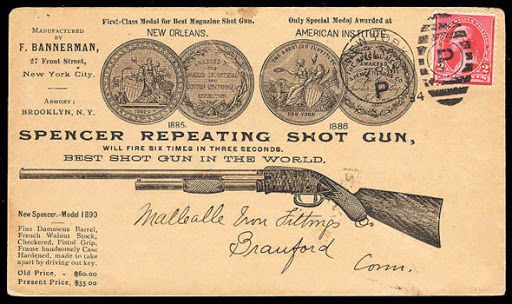

-Bannerman Model 1890

In the fall of 1890, Bannerman had restarted production of the shotguns while using up the last of the Spencer Model 1887 receivers till at least Serial #3326 and likely more. When they ran out of remaining stocks of receivers, they would then produce more with their markings as the “Model 1890”, and at the same time made the longer pump forend as standard, along with 3 other variations as seen in part #2. About ~9000 of this new 1890 model would be made over the next 3.5 to 6 years. These guns are marked as follows; and Serials on these go to around #12,000

F. BANNERMAN MANUFACTURER NEW YORK, USA

MODEL 1890

-Bannerman Model 1894(maybe)

Bannerman would later go on to market what they called an 1894 model… although, they are either very rare, or were just marketed in brochures as such to try and increase sales….as most Bannerman guns were very talked up in their ads to drum up business at that time, and pictures or records of ones marked as such have been impossible to find for me in the past 4 years. Those made after late 1893 started getting a new, more shapely forend that stayed till the early Model 1896s, and may explain the new marking if they exist. Serial numbers on these are unknown if they even exist…markings below are what these would have most likely been IF THEY EXIST at all.

F. BANNERMAN MANUFACTURER NEW YORK,USA

MODEL 1894

-Bannerman Model 1896

These models were pretty well unchanged, minus fore ends. In the early days they got a Gutta Percha rubber checkered forend but they were likely too fragile leading to all the different wood variations we see in part #2. These guns were basically identical to the model 1890 minus new markings, a stamped sheet steel magazine tube with trapezoidal teeth holding it together that holds the follower in a bit differently, and yet another new forend design. These guns were now marked as the “Bannerman Model 1896” and the forend was changed to the “Corn cob” fore end, or “6 groove style” that would be the standard continued for the entire rest of the guns production. These guns are marked as follows; and Serials on these go to around #18,163

F. BANNERMAN MANUFACTURER NEW YORK,USA

MODEL 1896

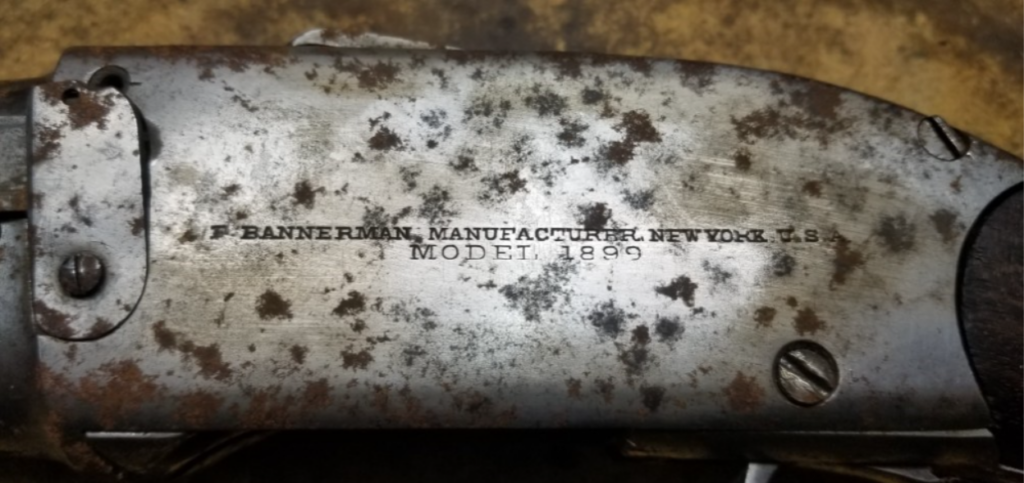

-Bannerman Model 1899

This is by far the most changed of all the models, and the last major revision made before production ended in ~1904. These are most easily distinguished from a distance by…. A 2nd left side ejector, a taller left control plate, large takedown levers, and the same 1896 grooved fore ends. They also are marked “Model 1899” on the receiver. One of the 3 examples ive seen is pictured below(#18163) with an unusual forend style that ive only seen on it.

The Model 1899 would now introduce the largest update on the design yet. This included a 2nd ejector and a taller left side plate, and larger much more pronounced takedown levers on the receiver with a crossbolt, and a magazine tube screw style change as well… although the left side plate being taller was mostly a mystery previously to me, it seems Othias has resolved it for me. This plate and the channel its machined into, along with a thumbnail groove is meant to allow you to remove the top screw, twist the sideplate 90* downwards, and reinstall the top screw. Then you can lock the plate in place with the lower screw and makes the takedown of the gun easier, and it retains the screws out of the users way.

Takedown on these was achieved by turning the receiver takedown lever downward 90*(no need to turn more than this), then unscrewing the mag tube takedown lever until the tube assembly comes off of the barrel, and then turning the barrel counter clockwise till it comes out. The mag tube can now be reattached to the barrel at this point for storage, as the follower and spring are retained in the magazine tube. This model was in production for a VERY VERY short amount of time, and in over 4 years of me searching for them i have only seen 3 pop up for sale, all having the same features and variations of parts and quality of work, and serials within 368 digits of each other….These are also marked as follows; Earliest serial ive seen was #18163, latest serial was #18531.

F. BANNERMAN MANUFACTURER NEW YORK,USA

MODEL 1899

-Bannerman Model 1900

The model 1900 seems to have been nothing more than a roll stamping update to the 1899. All features are the same and the only thing that seemed to be added was a slight update to the checkering on the front takedown screw from all the models ive seen. These guns were produced until around ~#21,954 ending around 1904ish after Bannerman sold off his tooling and machinery.

These also all should have come with the large teardrop takedown lever for the barrel and mag tube same as the Model 1899. Simply rotate the barrel lever straight down 90*(NOTE: do not remove this lever by unscrewing unless barrel is removed from receiver, and ONLY if you need to! The threads are weak!) Then turn the mag tube lever counter clockwise till the tube pops off, then pull the tube out and unscrew the barrel, while leaving the lever in the mag tube, the mag tube can then be screwed back onto the barrel for storage. Serials on these go to around #21,954

F. BANNERMAN MANUFACTURER NEW YORK,USA

MODEL 1900

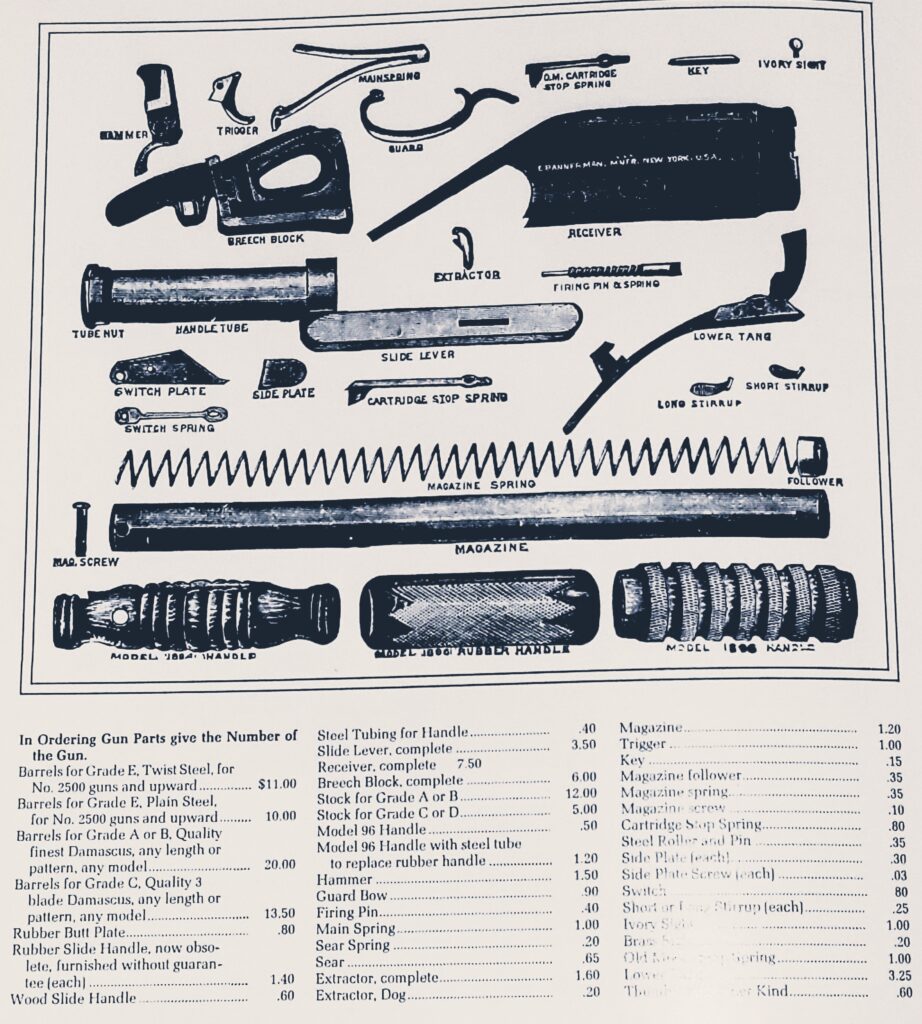

Breakdown with parts view(My Model 1900)

Myths(and opinions) on “Damascus/twist barrels”

Barrel making methods

Disclaimer: Everything below is from my educated best guess and should NOT be taken as gospel. Its ALWAYS worth consulting with a gunsmith, especially if you are firing one of these.

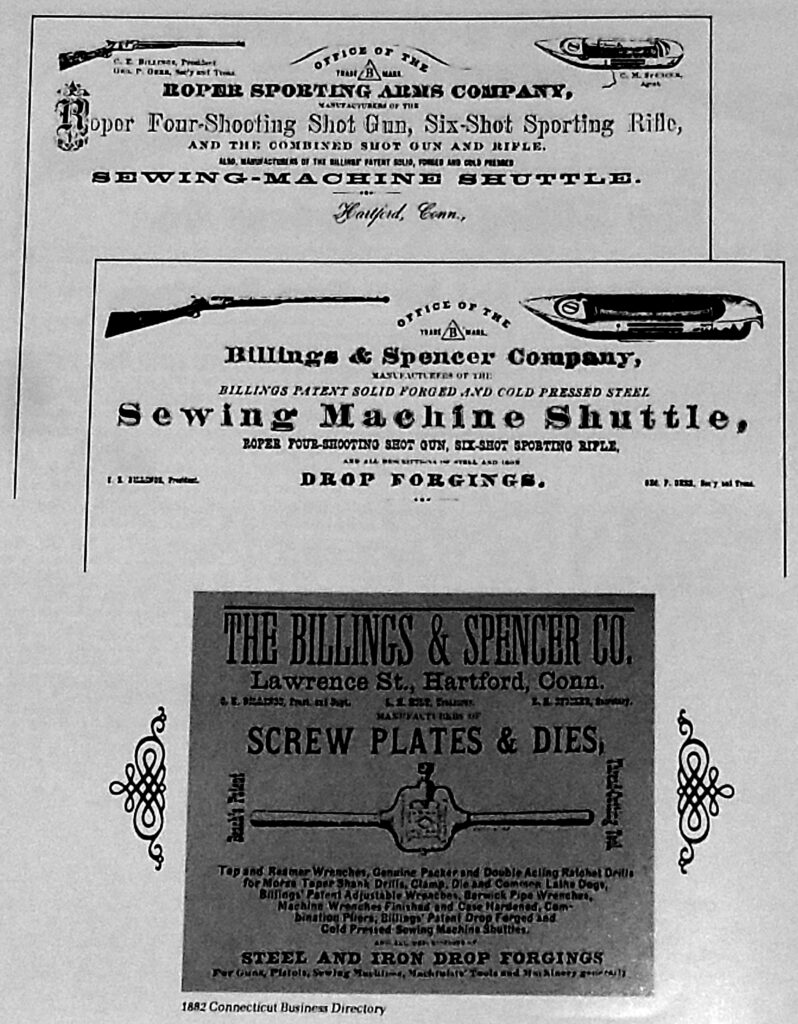

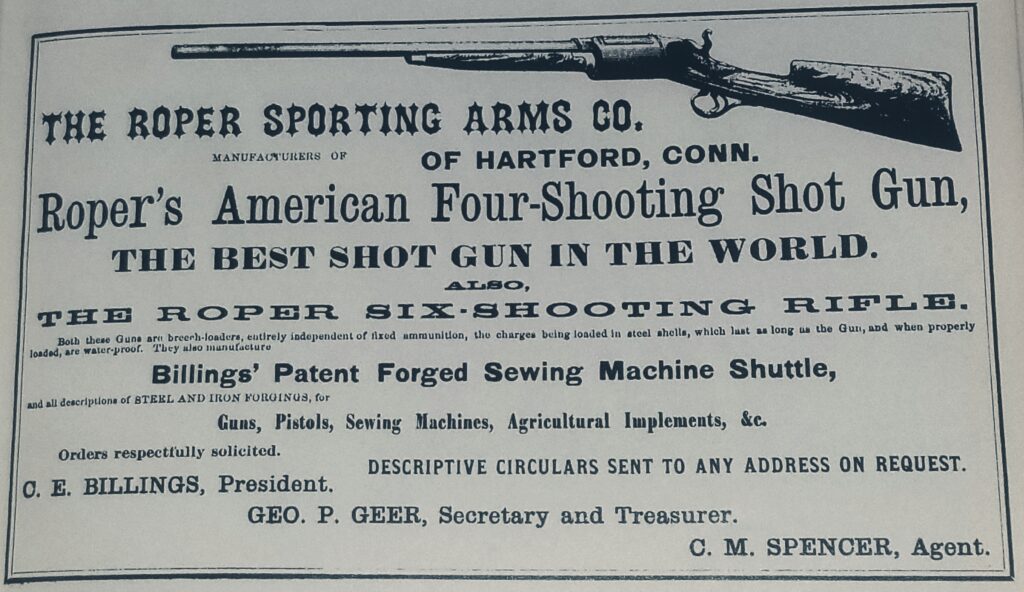

MY personal theory(which is well based after having my 1896 barrel and a model 1900s barrel sonar checked and research ive done) on their method of construction is, shotguns marketed as “twist barrel” DID NOT have actual twist barrels, they were acid etched to LOOK that way. The higher A/B grades with the “Turkish Damascus” WERE probably all Damascus and have a very different pattern, and makes more sense as the large price increase would have justified its higher manufacturing cost easily, and it also would make sense as they were typical patterns that are very common and were sourced from Turkish stock that matches other guns. But the “Twist barrels” were most likely fluid steel, as Spencer himself had YEARS of experience building fluid steel barrels for shotguns. This is how he made the barrels for the Roper guns(he still owned this machinery too) and had been making them for years for others with the Spencer and Billings company.

This leads me to believe that they would have done the same on the Spencer guns, and then used nitric acid as a way to imprint the colorized pattern in the steel as others had started doing as early as 1866. This acid etch process was beginning to catch a LOT of traction by 1883 in the industry and is a LOT LOT more common than people think it is. My grandpa used to talk about how his dad was always weary of pre 1885 guns but not many after that as many gun experts and shop workers had found they were found to not be real twist, but that they WERE 2 1/2 or 2 5/8ths chambered and the real reason they blew up was smokeless rounds. Plus, the fact that the forcing cone being much too tight, and or, the fact that smokeless generated too much pressure on top of that. Many post 1870 guns were proofed in other countries with twist barrels and found to be safe with smokeless as long as they had the glued in shot covers that didn’t expand into the cone rather than crimps that expand into the forcing cone.

Now i am no expert but ive researched it for over 4 years and shot TONS of low power smokeless shells with ZERO issues in good condition barrels out of many pre 1930 short chamber shotguns. But to stifle the occasional wonder, i took a Bannerman Model 1896, Bannerman Model 1900, and a LC Smith Field Grade made in 1899 to have them Sonar inspected by an old man who gunsmiths, and by the people at the machine shop i worked at. He said all were fluid steel barrels, and completely safe with correct low power smokeless shells and ALSO said that most post 1892 guns were not true Damascus.

Period Pictures

Annie Oakley’s press photos…She was a well known user who ordered one directly from Spencer for her show

Spencer Serial #1

Lancaster imported Spencers

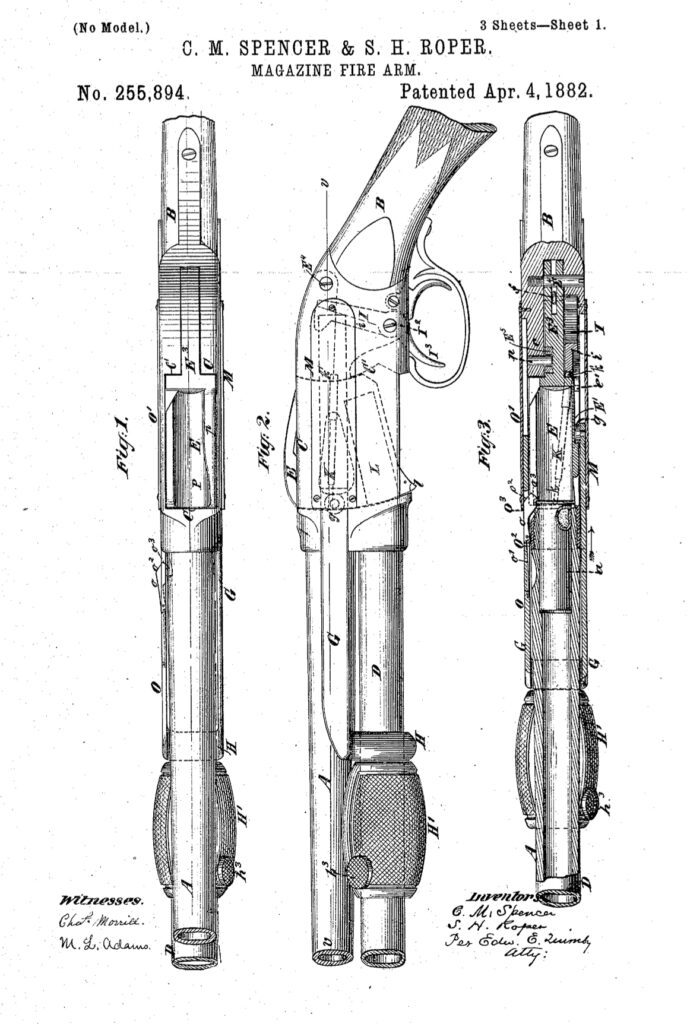

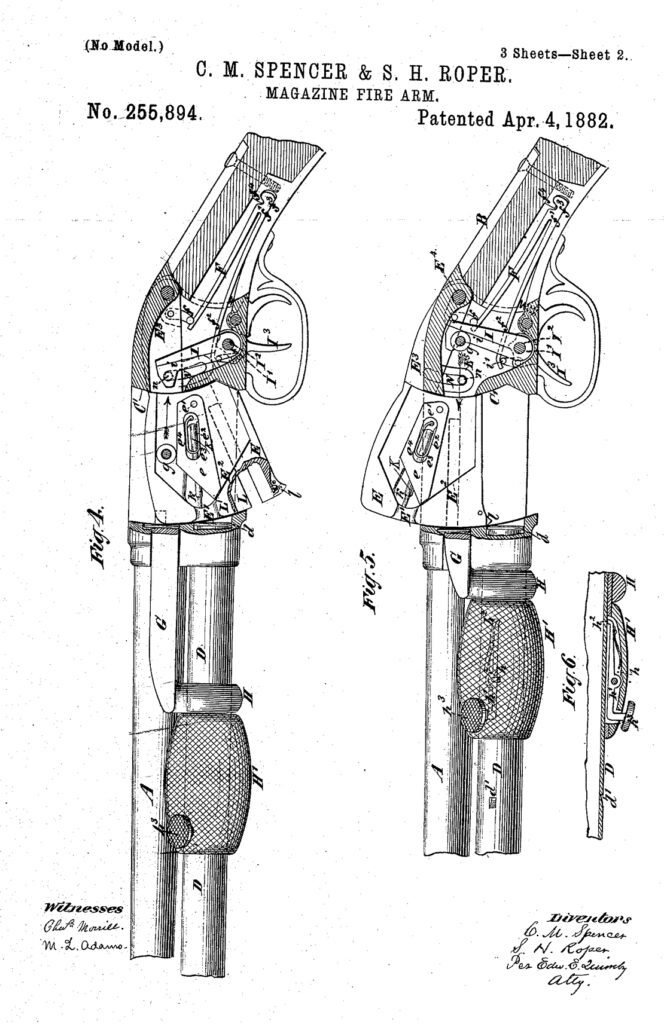

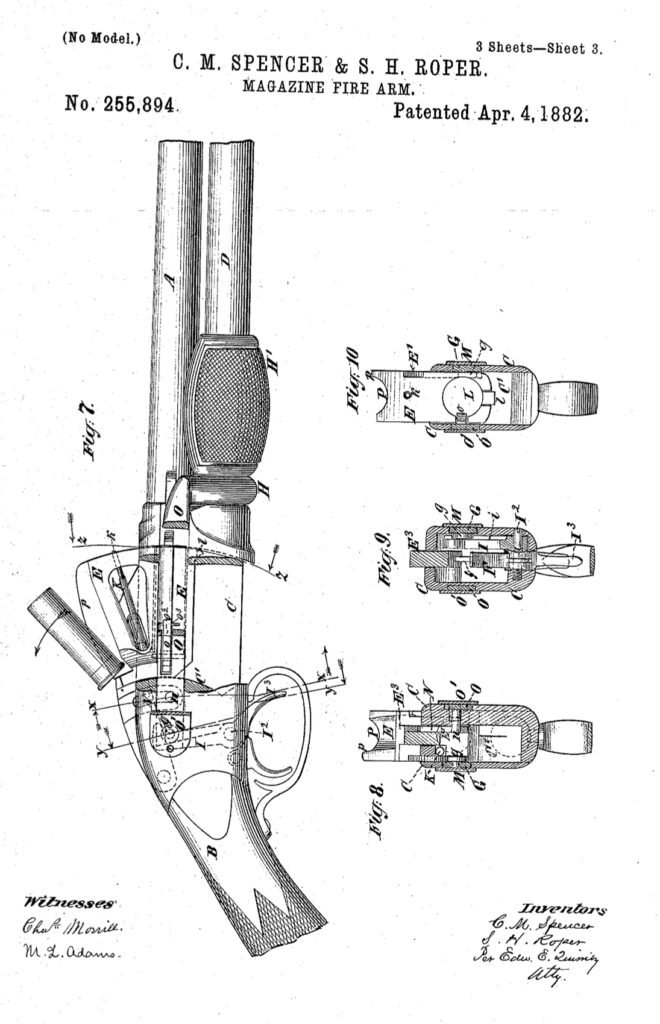

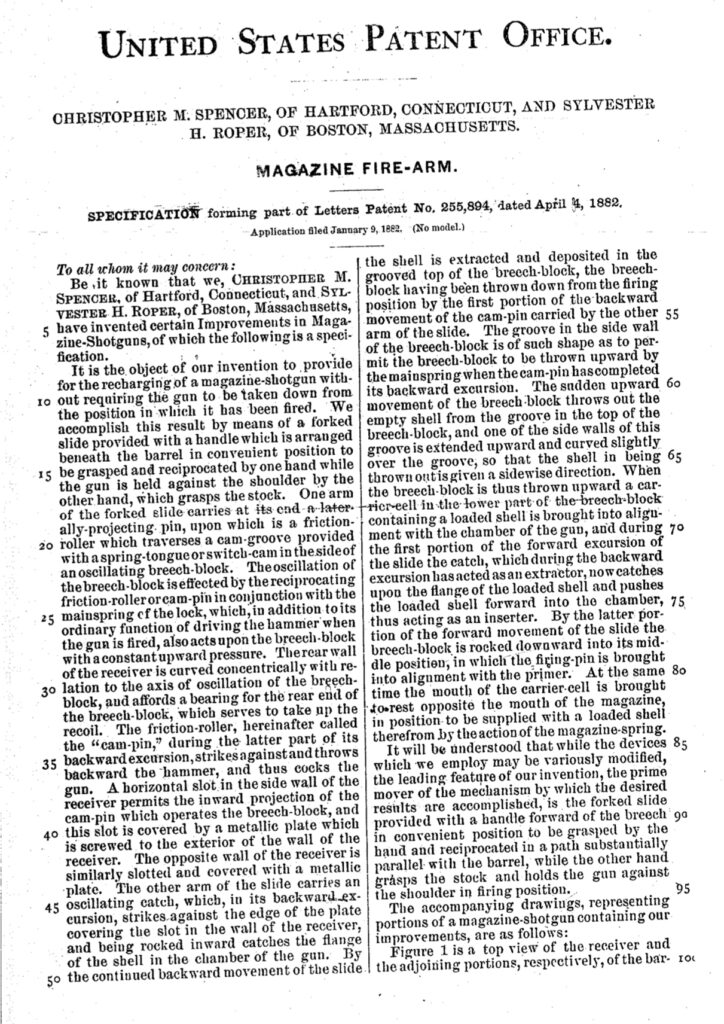

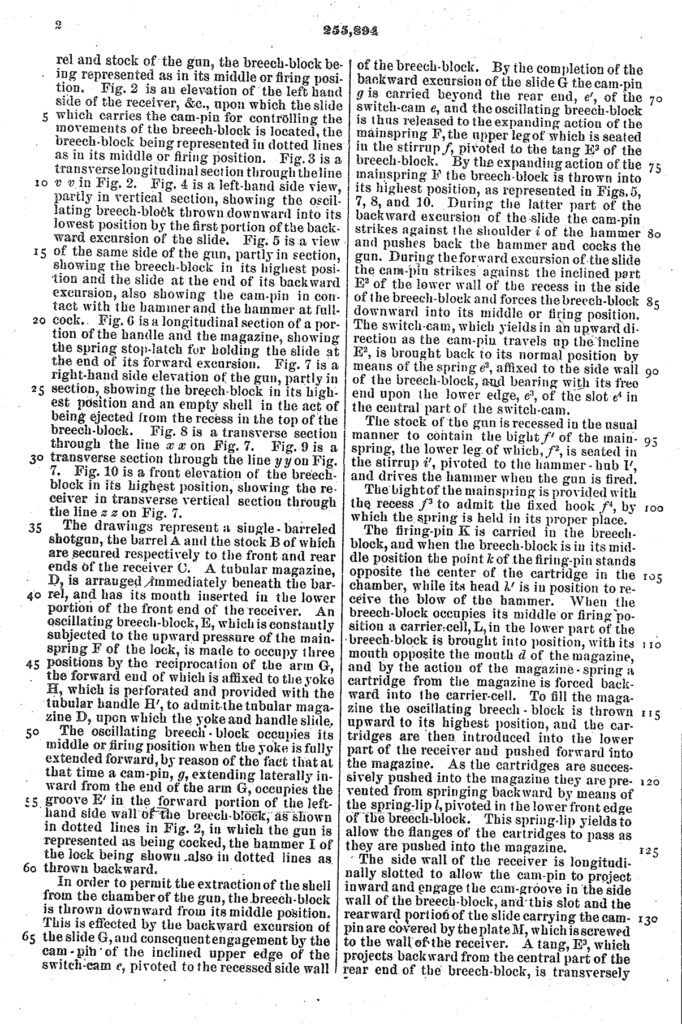

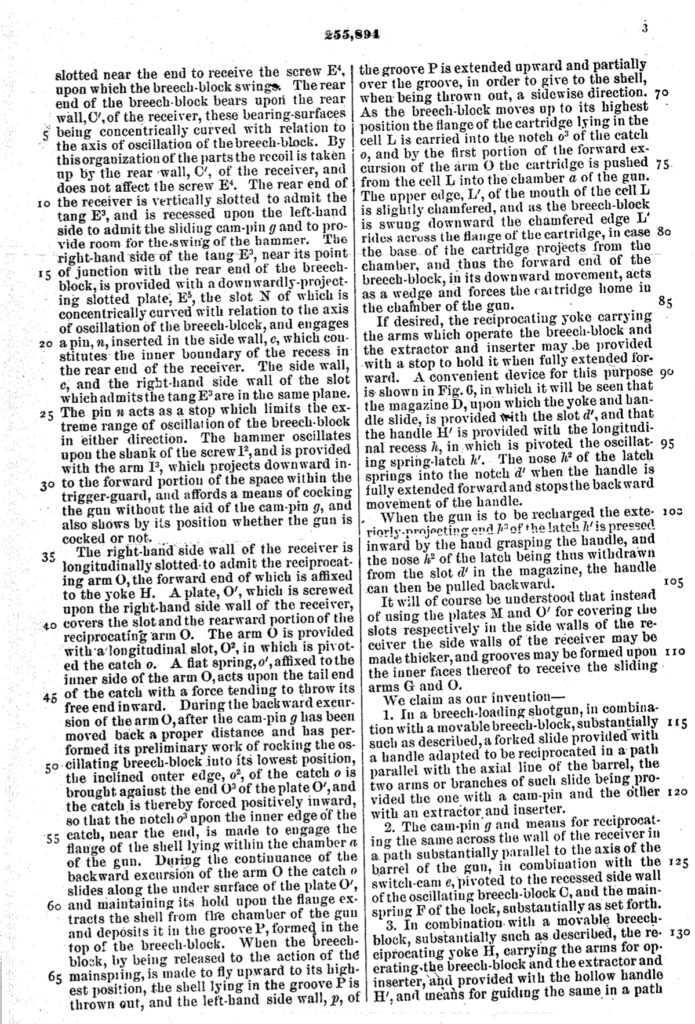

Patent drawings for the Spencer

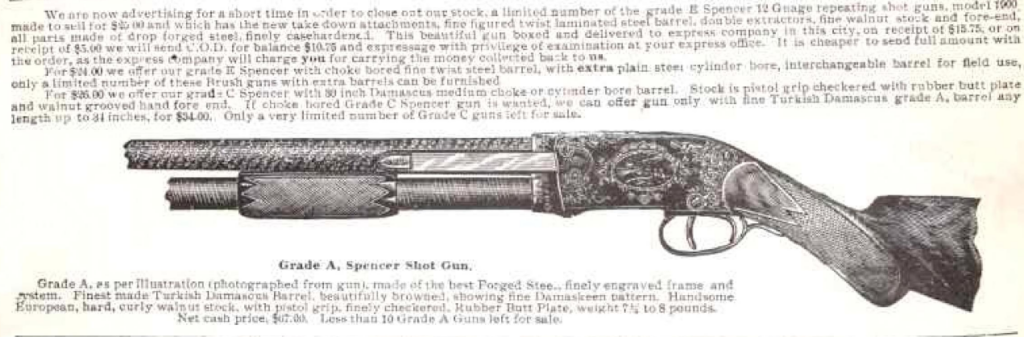

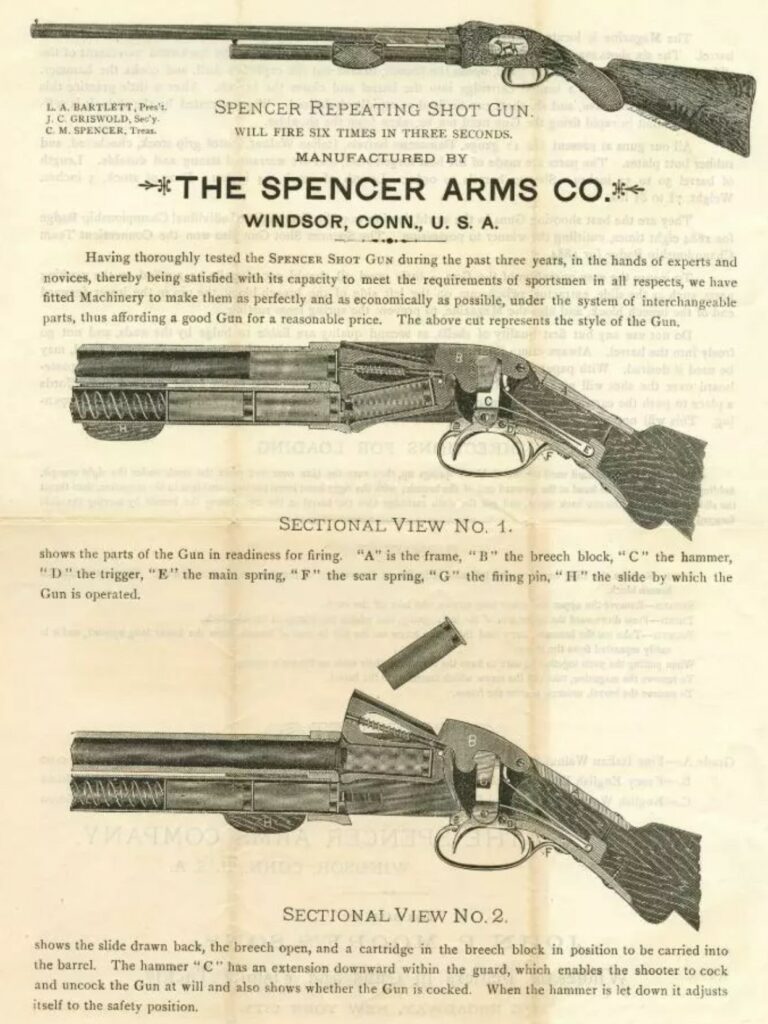

Period Ads

Other pics i have found

End part 3…This is the final post, it took me a lot longer than i thought it would do to tech and motivational issues but here it is. I will try my best to add more to it over time also.

See part 2 HERE

and Part 1 HERE

Thank You for reading this, and feel free to comment below with reviews and any questions/info you have! -Seth.

Special Thanks go out to Othias for creating this site and him graciously lending his pictures, and Morphy Auctions Co. & Rock Island Auction Co. for letting me use some of their photos!

Gun guy/gamer/Metalhead/LS car and truck guy.

I have a deep fascination in the mechanical engineering, manufacturing, and history of firearms. Especially rare, unique, and historically significant stuff. I especially like the period between stuff from 1860-1895 ish.

Excellent articles, Parts 1,2 , and 3 of The History of the Spencer. I would like to contact Seth Newman relative to several aspects of the Spencer Arms Co., proprietary subjects. George Carr

Thanks George, they need some revisions, just been slowly chipping away at it and havent finished those yet. also…. Im available on Discord, if you have/use it? Shadow0fd3ath24#9141 or you can find me under “Seth N.” in the C&Rsenal discord

I just tried logging discord and couldn’t find you or get an invite to C&Rsenal. My dad has some questions as well as some info. Can you please contact me? Thank you. By the way, my dad is a dinosaur and doesn’t have discord, only e-mail.

did you put a Zero (0) and not an “O” (the letter o) in “of” in my name? That will make me not pop up. it is a 0(zero). Their discord link is at the botttom of their main c&rsenal.com website

Or whats a good email for you?

my email is kattaklysm17@hotmail.com

thank you

replied to that email!