Part 1 of 3: This section will focus on giving you a deep understanding of the innerworkings of the initial history, the men, and companies incorporating into the Spencer Arms CO. It details the process that ultimately lead them to design such a firearm. It will also tell how the people around it grew up and where they came from, and how the guns were developed successively later on over the years. In the next part, i will explain any design differences, and any special variations and prototypes that i could find of the Spencer produced models. All info was taken from historical records included in Roy Marcots book, Cody Firearms Museum records, reasonably verifiable facts from books and websites, period advertisements, and from stories straight from C.M. Spencers son Percival. This starts with Spencers birth in 1833 and goes up till the end of the Spencer Shotgun company in 1889.

Authors intro: This will be a VERY detailed, 3 part bulk of knowledge about Spencer and his shotguns which I hope will be THE BEST source of info on these shotguns anywhere! It has taken a LOT of research, hands on experience with my 2 guns, along with 12 others, a trip to the Cody Firearms Museum by a friend, reading all of Roy Marcots Spencer book, and a large amount of time during COVID to compile all of this. This began after playing Hunt Showdown and seeing one for sale at a pawn shop(My Model 1900) and after buying and shooting mine, I developed a deeper interest in them and started doing(near obsessive) deep research into the history of these guns and getting as much info as i could. This is when i realized that there was very little info on these guns, and almost NONE online! I began compiling every picture and piece of info i could find on them to upload somewhere. Othias met that goal for a hosting website when he started Surplused.

Also… If you the reader have any photos, revisions, or otherwise pertinent info to share; PLEASE feel free to comment down below and i can take a look at it and see about possibly getting it added. All of MY written info contained here is hereby free to be used as fair use. If reprinted elsewhere then please cite Surplused.com as the source and Seth Newman(me) as the original author. All other pictures and info will either be approved for use by their owners and properly cited, one of my own, or already in the public domain due to being pre 1927! (to the BEST of anyone’s current knowledge).

The Beginnings of C.M. Spencer

Christopher Miner Spencer was born in Manchester, Connecticut on June 20th, 1833, one of eight children. He grew up on a farm until, at age 11 he went to live on the south side of Manchester, CT with his 90 year old grandfather, who taught him metal and woodworking skills that would come in handy later in life. His grandfather had served under Washington in the American Revolutionary war, and had allowed him to spend as much time as he wanted at an old foot lathe in his workshop working on designs and learning machining. When Spencer was 14, he received his first firearm, a flintlock musket his grandfather had carried during the Revolutionary War, thus sparking his love for firearms. Spencer had taken no time at all before he decided to improve and modify this rifle and he quickly chopped the barrel down “to make it more modern” for the time rifle(as he told his son Percival decades later).

Later that summer of 1847, at the age of 14, he went to work for the Cheney brothers in Manchester as an apprentice in their silk mill. Not taking the customary approach of a long apprenticeship tenure, he left just a year later, and went on to become an apprentice at Samuel Loomins, a machine shop in Manchester. Here he made his first machine, a small steam engine…and after 8 months of training, he took 12 weeks off of work to earn a formal education with Wilbraham Academy in the winter of 1848. In the spring of 1849, he retuned to Loomins and finally completed his apprenticeship, after which his grandfather passed away. By the next month at age 17, he went back to work for the Cheney brothers as an employed journeyman machinist. They encouraged him to develop his inventions further, which led him to develop a number of useful machines that cemented a relationship with them that would be lifelong. After four years, he was encouraged to move along and broaden his knowledge by his boss Frank Cheney, who helped him journey to New York to become a toolmaker, and later to work in locomotive repair shops for the New York central railroad. After this, he moved professions again to the N.P. Arms Company of Massachusetts where he got his first formal firearms experience and which led him to his next, and perhaps most prestigious and rewarding job at that time.

In mid 1854, Spencer returned to Connecticut to work for the newly formed yet very successful Colt company, where he helped personally construct many of the experimental machines for making Samuel Colts new designs come to life. After 2 years, he was persuaded to leave to join Cheney again, only this time as Superintendent for the new large “Silk Ribbon Manufactory”. At 22 years old, he worked 11 hours a day and 6 days a week and yet still found the passion and time for many new engineering and firearms ideas. It was during this time, that he conceived his idea for a repeating firearm and was allowed to freely experiment and build things in the Manufactory, under his bosses declaration; “but only in your spare time”. Silk Ribbon Manufactory kept the young man busy, but he still had found time to design and perfect a machine to attach labels onto rolls of silk for which he earned his first patent(US# 25,770). He was generously awarded by the Cheney’s and earned a $25 royalty on every machine they made using his design. This invention allowed one girl to do the work of three, and led the Cheney’s to become a much larger silk producer than they had dreamed of. Not long after this, in 1857, he designed a second machine which earned him another patent. This was for an improved thread spooler (US# 27,012) which also went to work in the Manufactory after it had increased production, making the Cheney’s very happy and earning him a raise.

The Spencer Repeating Rifle

After having conceived of his first repeating firearm in 1857, Spencer decided a year later in 1858 to spend his free time building a shop model out of wood. Even after working 11 hours a day 6 days a week, he found free time to develop what would ultimately be his most well known design. By mid 1859 he had a full scale model of a rolling block, lever action, repeating, magazine fed rifle model. This led him to be encouraged heavily by the Cheney brothers and his father to continue work on this new design. Spencer’s father then helped finance the initial working prototype (which ended up costing $293.67 to make in 1859) in exchange for a 50% share of future profits. He then constructed a working version that was crude but serviceable for showing his concept, and later test firing. After this, he contacted a patent attorney, and Spencer wrote a full mechanical description and had functional patent drawings made. He then filed the papers for this patent in late 1859, resulting in his most important patent(US #27,393) for his “Spencer Repeating Rifle” on March 6th, 1860. This would be the worlds first successful repeating rifle, and a huge success for Spencer after he had formed the Spencer Repeating Rifle company.

Once the Civil War broke out, the Cheney brothers became very interested in producing the gun in larger numbers for military contracts and bought the patent from Spencer for $5000, with Spencer also receiving a royalty of $1 per gun sold. Around this same time, and as early as Jan 1862, he successfully operated a steam wagon in Manchester and in Boston, and used it in going to & from his work which may have been the worlds first successful and practical automobile…This one had been coal burning of course, but those he built later in 1902-1908 used kerosene for fuel. He was reputed to have used this machine to get to the Spencer factory daily during the war.

Spencer would spend these next couple of years in the 1860s as their salesman and main marketer, and main production manager over the factory, only to struggle to get his rifle design militarily adopted. He eventually got a showing with Abraham Lincoln in 1863, who would personally vouch for, and help to get it adopted for the Union in the Civil War. It would quickly become the most produced repeating rifle of the Civil War and would help his company sell over 200,000 units in its 9 years of production. This would go on to earn the Spencer Repeating Rifle company over $2,115,465 from their military sales during the Civil War alone, including all of the rifles and accessories produced at the Spencer factory(not including the Burnside produced ones).

There were plenty of things to keep Spencer busy at the new armory at this time after production had gotten ramped up. He designed most of the specialized machinery to make his guns, and then had the machinery built not long after by other companies as contractors. Things proceeded slowly in the Chickering building on Tremont street, until machinery began to arrive and skilled workers were hired. By late summer, gun parts were being produced at a much faster rate and deliveries were catching up. Some key equipment had still not been delivered though, so Spencer called on his friend R. S. Lawrence, of the Sharps company, for help. Sharps barrels and lock parts were delivered which sped-up production, as Christopher Spencer had used Sharps parts in his prototypes and they again appeared in the early Navy rifles. By March of 1863, things were under control in Boston and things were moving along nicely. With deliveries catching up and no major new orders to keep business up, Spencer set off to tour the Mississippi flotilla and the federal armies in the west to demonstrate his repeater and drum up some business. This trip made a very favorable impression within the armies, but its direct result was only one order after much effort on Spencer’s part. That order came from Col. John T. Wilder’s brigade of mounted infantry, for 1400 rifles, but this order presented a serious problem as it did not come through the US Ordinance Department directly. The men of the brigade pledged their government pay and Wilder, a very successful businessman himself, cosigned the note for the purchase of these rifles. This meant that the guns would not be paid for on delivery, but rather as the men received their pay in the future. Given the state of the paymasters department at the time and their struggles, this presented a formidable risk, yet Spencer crossed his fingers and took the order anyway. At about the same time, the State of Massachusetts was having trouble with the federal supply of firearms for its State Troops, so they decided to solve this problem themselves and convened a board to select arms for their State Militia. This board later found the Spencer repeater to be the best of the 25 arms submitted. It didn’t hurt that the company was located in Boston for easy deliveries also, so it was officially adopted in April 1863. Finally in May of 1863, the state would order 2000 rifles from the Spencer company for their militia.

Up till July of 1863, only full length rifles had been built by the Spencer company. Most of these had been issued to cavalry and mounted infantry, but the rifles were too heavy and cumbersome for mounted service. Also, as they were not being equipped with a sling ring, there was a very great danger of losing the gun entirely if dropped, leaving the unfortunate trooper unarmed. This was contrary to most carbines at this time that had a sling ring, and that were tied to the horses. This, along with growing Cavalry force numbers, led there to be an almost immediate call for carbines by the cavalry forces and orders to start coming in despite no models being available yet. Spencer had originally built rifles because the Army refused to raise state cavalry regiments early in the war, as the belief in Washington was that the conflict would be over in less than the two years required to properly train a cavalry regiment. Now that those 2 years had passed, the Federal volunteer cavalry was becoming effective and had a true need for good carbines. And so, in June of 1863, as the last of the Army’s 7500 rifles were being delivered, the Spencer company approached the War Department with a proposal to deliver cavalry carbines. This was quickly accepted and led to a contract for 11,000 of the shorter Cavalry guns, with initial delivery to begin in August and to be complete before the end of the year. The price was set at $25 each and as usual, deliveries were late, but much less than before. The first carbines were accepted on October 3rd, 1863 with 7000 turned over to the Army by year’s end. This time the order was not reduced for late deliveries, and the contract honored rather than cancelled like had happened before. The worth of the repeaters was finally being appreciated in combat and the company continued to speed up its production. Before the contract was completed, the quantity was increased to 34,500 carbines total for the cavalry forces.

The Spencer Repeating Rifle Company was finally beginning to thrive, and although there would be more problems with production, the repeating weapon for the average trooper was finally beginning to be appreciated. The American Civil War was making the transition from the wars of the past, to the wars of the future thanks to the efforts of a single mechanical genius of the time. In all, during the War for Southern Independence, the Spencer company delivered 12,472 rifles, including 1003 for the Navy as well as Wilder’s and the Massachusetts guns, both of which were diverted to the Federal Ordinance Department. The number of M1860 carbines made by Spencer eventually totaled 45,785. An additional 30,502 M1865 carbines manufactured by the Burnside company were produce, but deliveries started just at the end of the war, so no Burnside made Spencers were actually in service before the Army of Northern Virginia surrendered. There were also a few thousand civilian sales in addition to government deliveries beyond the military. After the war, many troops took advantage of a government offer and purchased their Spencer’s when they mustered out at the close of the war. After the demand for the rifles dried up once hostilities ceased, the company could not compete with its own surplus, at the time being sold off by the government for much less than a new model. They introduced improved models, but the improvements were subtle, and not enough to compete.

Even after being perhaps the 2nd largest company in the United States behind only Colt during the mid 1860s, the Spencer Repeating Arms Company would ultimately fail to find enough buyers to sustain after surplus rifles flooded the market after the war. By mid 1868, they felt the pressure and were on the edge of bankruptcy, and in late 1868 after further financial issues, many companies including Winchester and Fogarty started to bid on acquiring the companies assets. The 3 year old, newly formed Fogarty Repeating Rifle company would go on to win the bid, purchasing the building and machinery by December of 1868, and continuing to furnish parts to the Army for their Spencers. This would continue up until the next year when they would also fail, and then be bought out by Winchester Repeating Arms company for $118,000 including all patents, assets, parts, machinery, and buildings owned by the previous companies.

Winchester would then go on to sell all the unneeded machinery of both companies at public auction on September 28, 1869 for a total of $138,000 for the machinery alone. This included many engine lathes, a 60hp steam engine for powering machinery belt drives, planers, 160+ milling machines, and lots more. This netted Winchester over $20,000 profits on machinery alone and made him a very happy man, while also ensuring that he had less competition in the market. The only problem was that he still had all of the extra complete Spencer rifles, parts, stocks, and unfinished rifle parts. This led him to send a letter out to potential buyers, and was responded to in December 1869 by Springfield Armories commanding officer, who was looking for parts to keep their current rifles in working order. Luckily the French government was also desperately looking for arms after their loss at the Battle of Sedan. Winchester promptly jumped on this opportunity, and provided the US government at Springfield Armory the parts they needed, and sold the French government every Spencer he had and even some of his own Model 1866 rifles.

Ventures after the Spencer Repeating Rifle

Fortunately for Spencer in the Civil War, he held no actual ownership in the Spencer Repeating Rifle company itself, and had simply worked as its plant superintendent, salesman, inventor, and mechanic. This decline in sales after the wars end led him to realize that his design would not last much longer, and that the companies direction would turn south. He found he was unneeded after the Civil War in the plant, and after not being given stock or being allowed to become director of the company which had his name and invention attached, he left in early 1866. Spencer had luckily made out very well, and when he left the company he traveled to Boston to meet up with a fellow inventor and fellow gun designer, a man named Sylvester H. Roper. Sylvester Roper was born on November 24, 1823, and from an early age he displayed much mechanical talent. He had built a steam engine by age 12, and a locomotive engine at age 14 off of a mere drawing, even before he had seen one in person. Roper left his hometown of Francestown at a young age and worked as a machinist, first in Nashua, New Hampshire then in Manchester, New York. By age 19, he earned his first patent for a padlock(US #2,248) and later would move to Boston, eventually working for Springfield Armory during the Civil War. Later he would invent a successful hot air engine in 1861, earning him his second patent. He would go on to build over 200 hot air engines, and earn a good living for the era.

Once together, Spencer and Roper got to work, eventually building and perfecting Ropers revolving repeating shotgun design, which lead to Roper securing a patent (US #53,881) for his design in April 1866. Later that year he would organize a manufacturing company to make and market them. Spencer would go on to become Agent and later Director of the new Roper Repeating Rifle company. They then commenced in making their first production model, a 16 gauge revolving shotgun. These would be sold till mid 1868, when Roper decided to recall all of them to fit with his new “Ropers Patent Muzzle Device”(US #79,861) which was the worlds first shotgun choke, and to be returned to buyers after the upgrades. In total, around 1300 of these guns would be made and by late 1868, they would introduce a 12 gauge model and produce at least 280 of those. Despite the quality and sales figures… they had high prices for the time and they would not go on to be a financial success or to compete well in the market. This would lead to Roper, and the neighboring companies president putting his metal button company, and the Roper arms factory up for sale. This led C.M. Spencer to jump on the opportunity and, with financial help from his father and his brother in law, he would acquire the plant in November 1868; This included all assets, machinery, tooling, patents, and jigs of the company. With Spencer now being the owner, a man named Charles E. Billings would join him to reorganize and build this company after Roper left. At 2 years younger than Spencer, Billings was an experienced gun manufacturer and also had extensive experience in tool making, die sinking, drop forging, and business management. He had worked as a designer for firearms makers such as; Robbins and Lawrence, Colt, Remington, and others. He had done various managerial, machining, and technical positions within each, and was the type to understand the business from all angles.

Spencer and Billings then moved the entire operation from Amherst, Massachusetts to Hartford, Connecticut and reorganized as the Roper Sporting Arms Company. Located at Rifle Avenue in Hartford, they opened their doors March 2, 1869. Having listing their capital stock at an amazing for the time sum of $600,000. Billings was appointed President, and Spencer and another man named Perry were appointed as its directors. 12 gauge shotguns, .40 cal rifles, and unique combination guns were made there beginning in 1869, but only about 600 guns of any variation were made during this time and all were marked as Roper guns.

As sales declined further for the Roper marked guns, the company then started another division known as the Spencer and Billings company which focused on making and selling sewing shuttles, small gun parts for others, and hand tools. Eventually they started to put their gun making machines to use in manufacturing instead, including drop forging for others. Their first year had ended very successfully in over 107,800 forgings being made with gross revenue of $52,500. Around this era they had 3 large buildings and many more storage and shed buildings to keep up with demand. With over 8 months of backlogged work, they eventually became a large growing company with many contracts, including making enough parts for the Prussian government to complete 1000 guns a day, meant for their newly adopted Dreyse Needle Rifles. They also were making sewing machines and sewing shuttles, bobbins, rifle and shotgun parts, screws, knitting machinery, machinists tools, hand tools, saws, wrenches, and many other forgings for anyone they could.

Later in December 1872, Spencer moved out of direct management of the Billings and Spencer company, retaining his stock and moving on to putting his inventive mind to work in other ways. Around this time he invented a machine that produced hundreds of sewing bobbins very quickly, and got the idea for a new machine to do the same thing only for making metal parts, and eventually screws. After months of working on it and perfecting it, he received a patent(US #143,306) for his new machine, the worlds first “automatic screw machine”. This new invention also had the huge benefit of the fact that it was able to be adapted as what we now call a turret lathe, which would go on to become one of the most important machines of the Industrial Revolution. Unfortunately the adaptability of the machine was something Spencer had forgot to include in his patent application specifically. Unfortunately for him, another inventor soon secured this wording for their patent leaving Spencer unable to, and yet Spencer still made a fortune off of his patent screw machine in his later life. In 1876, he and a few others organized a company to utilize his newly improved screw machines in manufacturing, which became the Hartford Machine Screw Company, with a capital stock of $40,000. It grew quickly, and within 3 years was one of the largest companies in Hartford, making screws and other fasteners by the millions. Spencer remained an officer of this company until leaving in early 1880 to pursue firearms again with Sylvester Roper.

Inventing The Pump Shotgun

In late 1880, Sylvester H. Roper recontinued his interest in designing firearms by beginning to build a prototype of a new repeating rifle that worked by means of what we now know as a sliding pump handle. Soon after it was complete and had shown some promise, he persuaded his former business associate, and repeating rifle veteran Christopher Miner Spencer to join him to refine and perfect the design of this new firearm. By January 1881, they had a full size working model of a slide action repeater, only now it had morphed into a shotgun with an unusual pump handle(See fig. 1).

As we know, Roper and Spencer had been known for doing unique repeating shotgun designs earlier on, and had later made Ropers prototype shotgun into a firing model. This encouraged them to continue refining and working on the design separately over the next few weeks. After Spencer returned back to Hartford CT, he decided to build another model, this time with help from a man named Joseph Frazier in the early spring of 1881. This was a 20 gauge shotgun with a 25″ long barrel that was bottom mounted, with a top mounted full length magazine tube, no markings or serial number, and 1 trigger, unlike any other Spencer/Roper designed repeating shotgun. This model is currently in the Smithsonian Collection(See fig. 2)

During this time, Roper worked on the shotgun magazine design that he owned the patent for, and later he and Spencer came together again in March of 1881 to design a Lee type box magazine fed rifle version, chambered in .45-70. This Spencer-Lee rifle was made to compete in the Army Ordnance Board competition for a new breech loader. It was eventually declared unusable due to unreliability as either a repeater or single loader by the testing board, and later lead to them refining the design and requesting a retrial. After sorting out the magazine issues, they lost the competition to the improved Springfield 1866 which would later become the Model 1873 “Trapdoor”. Later on September 3, 1872, an Army Ordnance Board convened to select the best breechloading carbine and rifle for the U.S. services. One of the 99 firearms tested, one of these was submitted by Christopher M. Spencer, and was a very basic and behind the times design as it was a single shot weapon, with an 1860s style lock and external hammer from his previous Spencer rifle, and a simple rolling block similar to the Winchester low wall rifle(See fig. 3). Other than the side lock and hammer mechanism, it had no relation at all to Spencer’s Civil War repeater, nor to Roper’s cylinder magazine repeater, and the rifle was later patented by Spencer(US #135,671). The improved Springfield Model of 1873 would go on to be adopted. The reason for the unusual design of Spencers gun, despite being known for repeaters, was due to a previous agreement between Spencer and the Winchester Repeating Arms Company on August 22, 1870. Spencer had agreed to assign all rights and title to any of his repeating rifle patents to Winchester, including any potential repeating rifle patent that Spencer may get in the future. However, this did not stop him from designing, patenting, and making single shot rifles, repeating shotguns, or pistols of any configuration.

Later in the Summer of 1881, Spencer had yet another improvement on the design of their shotgun and prototype drawings were then given to the Billings & Spencer Company, which made several working prototypes of this new design, of which about a dozen models were made and none are currently known to exist. Spencer then spent the rest of the year devoting his work into refining his version of this design and improving it for reliability and possible production. He would secure a Patent in April of 1882 along with Roper, and after further meetings and refinements, a company was formed to manufacture and market them. The talented design duo then convinced New York financiers in 1883 that their repeating firearm designs would be a success due to their experience in the firearms industry and manufacturing. They also had the perk of the easy adaptability of the design to other types if needed. And so, on May 9th 1883, the Spencer Arms Company was formally incorporated. With its capital listed as $400,000, and Lester A Bartlett, Fredrick M Peck, Edward E Gedney, Thomas O’Neil, and Henry H Sawyer listed as the companies officers, they began working to secure machinery and outfitting their plant at Windsor, CT.

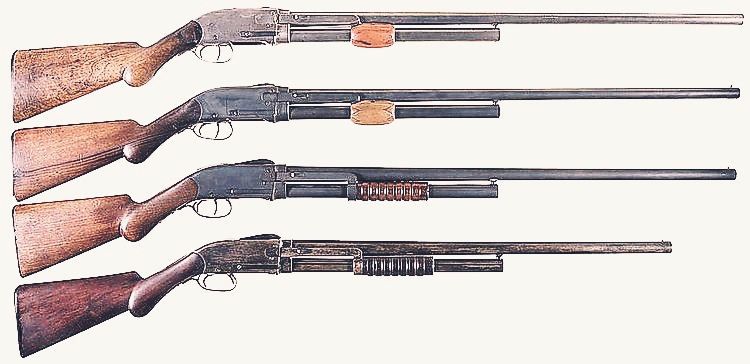

Model 1882 Spencer

By years end, most effort at the Windsor factory had been put into tooling up for production, and in early 1884 they would begin producing the “Model 1882” 12 gauge repeating shotgun design. By August of 1884, the local newspaper reported that they employed 65 people and produced 5 to 10 shotguns a day. AT LEAST 369 shotguns were made by years end as denoted by a note from a happy customer from Minnesota named C.R. Frazier that had purchased Serial #369 in late 1884 at some point. Altogether, around 800 of these guns would go on to be made between 1884 and 1885 in Windsor. The companies first catalog printed in 1885 listed 3 grades of shotguns and these were available with 30 or 32 inch barrels, with shorter barrels available “by custom order”. Around ~70 of these were shipped completed, but without wood and unassembled for reselling by the English firms of Charles Lancaster, and a few by Rigby’s gun store. Some of the later models around Serial #600 or so also started to have to 2 screw control plate scheme as seen permanently on the 1886s. These have a hard rubber or wooden(very early ones) checkered foregrip. About ~800 of these would be made from earl 1884 till late 1885

Spencer would have one of these early models custom made for his wife Georgette, a deluxe Grade A model with special custom engraved scrollwork and an inscription on the right side saying “G.T. SPENCER July 3, 1885”, and the other side showing a scene of a woman shooting upward, and a dog retrieving a duck. Another Ultra Deluxe custom model was also ordered by Mexican president Porfirio Diaz, in early 1884, Serial #280. It has a 32in barrel with silver plated receiver and action bars, Turkish Damascus magazine tube and barrel, and special high grade walnut furniture. The receiver and breech block are fully engraved and inlaid with gold scroll work and the action bars are partially engraved. The right side depicts an eagle, and the left side shows 3 more birds in circles done by engraver Robert Steel. (See fig. 4).

Model 1886 Spencer

In 1886 the Windsor plant released a second model of the shotgun with the only difference being the “SPENCER ARMS CO.WINDSOR.CT.U.S.A.PAT.APR.1882” markings added to the top of the barrel, and a second screw added to the top of the control plates as standard on the side of the receiver. A 20 gauge model was also prototyped again by Spencer around this time, but never went into production, it had a Nickle plated receiver and featured a control plate that stretched almost the whole side of the receiver. About 1,300 of the 1886 models were made in their only year of production.

Model 1887 Spencer

The 3rd and final model of the Spencer made guns were the “Model 1887s”. These were basically identical to the Model 1886 and had the same markings, but had the shorter side plates that would continue until the model 1899. According to an 1888 ad, these also came standard as takedown models, though this could just mean the barrels werent torqued on fully, so they could be unscrewed by hand. These were produced by the Windsor, CT plant from 1887 till the companies bankruptcy in 1889. Only ~1100 of these were made in the final 3 years of production.

Springfield Armory Tests the Spencer Shotgun

In January 1886, the Spencer Arms Company submitted a slide action, 12 gauge shotgun to an Army Ordnance Board at the Springfield Armory. They had entered it into this hopes of gaining a favorable report to obtain future military contracts. This Spencer shotgun was, in all specs, identical to any other Model 1886 gun. It was tested from January 6th to the 23rd by Captain W.S. Starring, Captain F. Heath and Lieutenant C.H. Clark: the results were, for the most part, quite favorable. A total of 354 Spencer 12 gauge shotguns were eventually ordered by the Army Ordnance Department.

On December 24, 1887, an additional ordnance board at the Springfield Armory tested ten Spencer shotguns. In the preliminary tests, brass shotshells manufactured by Parker Brothers were utilized, but the guns experienced many misfires. The initial conclusion was the mainspring was too weak, but when shotshells made by UMC were tried, no more misfires occurred. Minor problems were noticed during feeding, but ten guns were accepted, serial #’s 1810, 1816, 1826, 1830, 1845, 1848, 1854, 1876, 1880 and 1889. Two weren’t accepted with serial #’s 1815 and 1896. Yet another Ordnance Department test of Spencer shotguns took place at Springfield Armory on September 1, 1888. This led to to the testing and acceptance of shotguns numbered; 2793, 2794, 3044 and 2545. Each was fired with shells loaded with 3 1/2 drams of black powder and 1 1/4 ounces of #8 shot. There was also a mention of them in The Chief of Ordnance Annual Report in 1886 that references their intended use. “SHOTGUNS FOR GUARDING PRISONERS”; The over penetration of their rifles would make firing in populated areas very dangerous, and the Department purchased a limited number of repeating shotguns for use by guards to avoid this.

The Later years of the Spencer Arms Co

Despite the Spencers earlier higher sales and high praise, the small amount of ~1100 guns in their last 3 years of production were not enough to sustain the company, and led to financial issues in mid 1889. Bankruptcy came soon after in November once payments to creditors and machinery companies like Pratt and Whitney(who owned the tooling) had stopped, and could no longed be payed along with other debts. The full assets of the Spencer Arms Co were eventually sold at auction in full to Francis Bannerman of New York in December 1889. Notable users made the gun famous, and Bannerman would go on to sell more and more of them, while the original models were used by hunters, and competition shooters such as Annie Oakley, as shown below. She was an early customer of Spencer’s and used it all throughout her time with Buffalo Bills Wild West Show, and is thought to have owned it until her death in 1926.

When the Spencer Arms Co went bankrupt it was liquidated fully to Bannerman, and instead of payment for previous debts, C.M. Spencer gave all assets owned by him to Bannerman. He then took his wealth from his screw machines and other inventions and ventures, and finally moved on to relax away from the gun business. He would spend the rest of his life spending time with his wife and children and continuing to tinker and invent new things. His steam cars he had built in the 1860s led him to want to build another steam powered automobile, this time a much better design with a typical style body and chassis. He would use this to get around town, and with help from his son Percival, he would later dabbling with aeronautics and airplanes. Having come up with what would later be proven to have been a successful helicopter design as early as 1915, he would continue to dabble in aeronautics and invent things till he died at his home in Windsor, Connecticut on January 14, 1922 at the age of 88.

End part 1…To be continued, click HERE for part 2

Thank You for reading this, and feel free to comment below with reviews and any questions/info you have! -Seth.

Special Thanks go out to Othias for creating this site and lending his pictures, DarthRayden for their help when needed, Chellman910 for his pics of his very late 1887, and Morphy Auctions Co. & Rock Island Auction Co. for letting me use some of their photos royalty free!

Gun guy/gamer/Metalhead/LS car and truck guy.

I have a deep fascination in the mechanical engineering, manufacturing, and history of firearms. Especially rare, unique, and historically significant stuff. I especially like the period between stuff from 1860-1895 ish.

I have the early 1882 shot gun with the single screw operating rod cover. My operation rod is broken where the extractor pin passes through the operation rod. Can you tell me someone that might have a replacement operation rod.

Thank you

Scott Moore

205-393-7195

youre gonna either have to buy a whole new gun or have it fixed, those guns dont even share the same op rods with the MUCH more common bannermans and are 140 years old….. or watch gunbroker like a damn hawk and hope one pops up lol but even this itll probly be the wrong one…The only place ive seen parts other than GB for one is there or at wannamachers….and those were just a magazine tube in 2017 and a trigger guard in 2019 for a bannerman that were in random parts lots.